It’s an obligatory subject for those heading out on a overland journey with a heavy Expedition Truck – drive 20 inch split rims or standard 22.5 inch rims? Over the past 10 – 15 years there is a noticeable shift towards 22.5 Inch rims. If this trend continues, will the 20 inch split rim become extinct?

20 and 22.5 inch truck rims

The 20 Inch split rim is historically a widely used rim size and in this article taken as the size for comparison with a standard 22.5 rim – which is currently the popular rim size in the truck transportation sector.

An example of a 20 Inch spilt rim with a Continental HCS 14R20 tire:

Nowadays the 20 inch rim is remains popular for off-road use. The 22.5 Inch has gained huge popularity on tarmac and has become the standard in many countries.

This article compares the two rim sizes and looks at the pro’s and con’s in the context of world wide overland journeys by Expedition Truck. The comparison is by no-means the truth or complete and certainly not meant as advice in any way of form.

When 20 inch split rims are essential

No question about it – there were times when 20 Inch split rims or Trilex rims were an essential part of a truck outfit. Road side tire repairs back then was as normal as life due to many factors. The difference between on-road / off-road wasn’t so clear in the old days – roads were bad allover the globe compared to current standards.

Here's a typical gravel road in India - most trucks have 20 inch split rims, but the balance is shifting towards cheaper 22.5 Inch rims and tires.

Nowadays tire quality has increased significantly, load ranges have gone up, tire distribution networks have widened and tire workshops are better equipped. Also the transportation sector is better controlled by police nowadays, adding significantly to road safety. On top of that yearly obligatory TuV / MOT inspections made the road side tire repair a lot less common nowadays. So basically what defines in this day and age the need for driving 20 inch split rims?

Load, Usage, Destination, Footprint and Fuel

By far the most critical parameter that sets the perfect conditions for a flat tire is wheel load. Add terrain conditions (bad roads, mountains etc), usage scenario (speed, cargo distribution etc) and the perfect scene is created for running a flat tire. The region / destination determines how easy it is to recover from a flat.

Example of an 8 lug 20 inch split rim;

No doubt, when exploring remote regions in difficult terrain, 20 inch split rims is (still) the best choice. Being self sufficient is key in extreme conditions where a flat tire can be a weekly or sometimes a daily event. Same for some Asian / African countries where 22.5 inch tires are (still) hard to get leaving 20 inch the norm for now.

But the 20 Inch rim in combination with a the popular 14 inch off-road tire has 2 other benefits. First keeping fuel consumption down by reducing engine revolutions by choosing the tire with the largest circumference, which is in most cases 14 inch. Second by creating the longest possible footprint for sand driving by reducing air pressure.

Nonetheless the balance is shifting – the distribution of the standard 22.5 inch rim & tire is spreading globally. So apart from destination & region what are the pro’s and cons of driving 20 of 22.5 Inch rims?

20 Inch versus 22.5 Inch rims

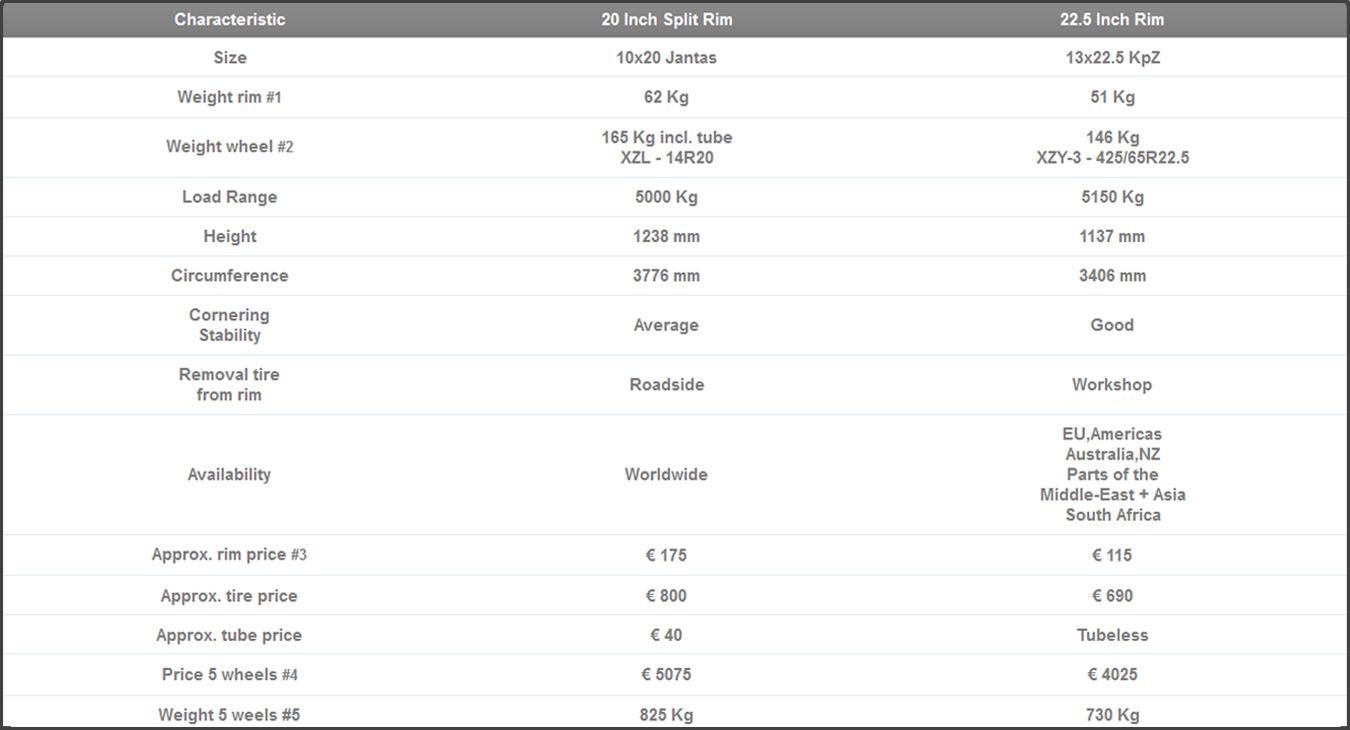

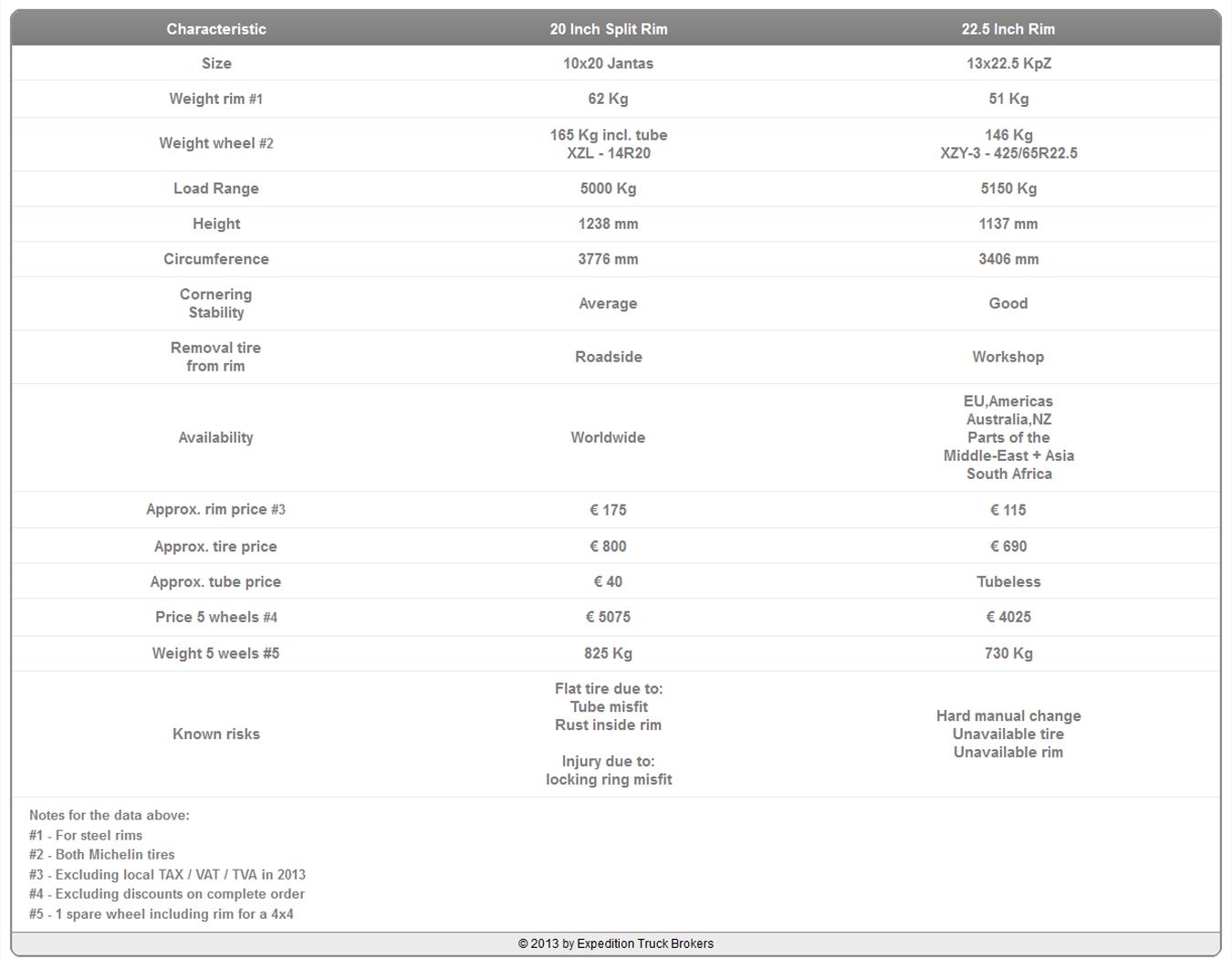

Below a summary comparison of 20 and 22.5 inch wheels. In overlanding a 14 inch tire on a 20 inch split rim size is quite common. Though with the 22.5 inch standard truck rim the scene is more diverse – there isn’t a commonly used truck tire size in overlanding (yet).

In this comparison a large 22.5 Inch tire is taken as close to the size of a 14R20 (Michelin XZL) and commercially well available – the Michelin XZY-3 for mixed road use.

The XZL tire has an aggressive profile which is plus in the mud, the XZY-3 has a more even profile and balloon type appearance which is a plus on tarmac and sand.

In short the key differences between 20 and 22.5 Inch tire set

1. Weight – For the same weight, the difference is approx. one 22.5 inch tire

2. Price – For the same price, the difference is approx. one 22.5 inch wheel

3. Stability – The lower sidewall with 22.5 inch rims has better cornering stability

4. Availability – The 14R20 tire is easier available in 2nd . 3rd world countries

Nowadays there are also 20 inch tubeless split rims and variants made from aluminum (alloy) to save weight. However alloy split rims have a lower load range dipping below the load range of an average 14R20 tire.

For now the 20 inch rim is here to stay - though 22.5 inch is already the dominant size in worldwide production volumes. The market segment for 20 inch will undoubtedly become smaller with the inevitable impact on the pricing of the 20 inch tire.

Will this announce the era of the 22.5 Inch split-rim for Expedition Trucks? Time will tell !

Truck Orientation Service - Start better prepared

Want to start your future overland journey better prepared? Consider our Truck Orientation Service.

This service is packed with many heavy truck-related topics useful for those starting their overland journey.